Heritage Guns’ ‘Accipiter Series’ shotguns

The Accipiter Series of ‘drop-gauge’ shotguns

started with an 1870’s bar action hammergun by Watson Bros. Bought

at auction as a ‘stock and action’ with slotted barrels (to

conform to the UK laws governing the sale of out-of-proof shotguns),

there was never any doubt that the only future for this gun lay in TIG

sleeving. However, rather than sleeving the gun as a 12g, I decided

that, given its elegant, slim, lightweight proportions, it would make

an excellent basis for a long barrelled 16g, tall bird and clay gun.

Judging by post-sale comments from the Watson's first owner, this plan

was a great success and so I determined to produce a series of like

guns.

Watson Bros 16g Bar Action Hammergun No 4820. Barrels 30" x 2 3/4". 6lb 8oz

The origins of the idea of sleeving guns to a gauge size lower than

their original came from a series of conversations with an enthusiastic

S/S shooter from Virginia. Being a gentleman of generous height and

build, he found normally proportioned guns quite unshootable and we

discussed the possibilities of building long barrelled, heavy, sub-gauge

guns on actions originally designed for larger gauges.

As it turned out, the target weight that he required was just not possible

using a normally proportioned English game gun and so the half-finished

project was finished off for stock. This was the second gun in the then

unnamed series, an 1890’s William Cashmore of Birmingham BLE.

William Cashmore 16g Boxlock Ejector No 2228. Barrels 30" x 2 3/4". 6lb 9oz

One should not confuse ‘sleeving’ with ‘lining’,

a novel process developed by Nigel Teague. Sleeving involves boring

out the first 4” or so of the old barrels from the breech end and

then cutting off the old tubes, usually at around 3 ¼” from

the breech face. A pair of new tubes are then ‘top-hatted’

into the old breech piece, or monoblock as some would have it, and TIG

or Laser welded in place at both the external joint and breech face.

This leaves you with a continuous new barrel internally, from breech

to muzzle, and the old barrel externally for only 3 ¼”.

The joint area is ‘normalised’ to negate brittle cracking

and soften the weld zone, the barrels are ‘struck up’, ribs

re-laid, rim recess and chambers cut, barrel rejointed to the action

and then finally the gun is submitted for nitro proof. Say it quickly

and it does not sound too big or complicated a job. Believe me, done

properly, it takes time and is nothing short of alchemy!

In contrast, Nigel Teague’s ‘lining’ involves the retention

of the full length original barrels externally, bored out to accept

a full length liner. This is a hugely challenging technical process

and I take my hat off to Nigel for developing such a novel process.

And the name for the series? Well, anyone who has spent time round hawks

and falcons will know that Accipiter is the genus that includes Goshawks

and the European Sparrow hawk among many others. These birds are very

proficient hunters, much to the chagrin of many gamekeepers, and often

demonstrate power out of all proportion to their size. For example,

UK falconers flying female goshawks often specialize in taking brown

hares that weigh 2 or 3 times that of their bird. Having personally

experienced the potential of a long barrelled drop-gauge for clay and

game shooting, I thought the parallel with these fabulous birds of prey

was appropriate.

The third gun in the series came from a chance visit to my local gun

shop, Simpsons of Newmarket, run by Barry, Sue and Paul Simpson. If

the name of Barry Simpson seems familiar it is not surprising as he

held the World FITASC Championship title in 1985. Anyway, the visit

produced a very cute 1910 20g Westley Richards BLE with thin and heavily

pitted barrels. This looked like a perfect candidate for sleeving to

30” x 28g and this is exactly what I did.

Westley

Richards 28g Boxlock Ejector No D9546. 30" x 2 3/4". 5lb 14oz

After the WR 20/28, I found myself with a left handed 12g by H Clarke and Sons of Leicester. I had been looking for a suitable 16g gun to shoot myself to ascertain whether rebarrelling my late father’s 12g J Blanch & Sons BA SLE to 16g was a worthwhile idea. After almost 4 years of snatching a hour here and an afternoon there to work on the project, I can say that today (May 2015) I finally got to shoot her in anger: 75% on sporting clays is about as good as I ever do and I bettered that on my first outing so it looks good! The configuration and design of the Clarke is very similar to the Blanch and I plan to shoot the Clarke for a full season before making a decision.

H Clarke & Sons 16g Back Action Sidelock Ejector No 10105. 30" x 2 3/4". 7lb 1oz

The next two guns to get the drop-gauge treatment were both made by

that doyen of the London gunmaker fraternity, Holland & Holland,

but were very different in their style and design. The first was a ‘No

2’ model: a back action 12g, converted to ejector around the turn

of the C19th, with damascus barrels and lovely, classic H&H style

stock. The sleeving to 16g was trouble free but the ejector mechanism

has proved more challenging and we have returned it to extractor only.

Holland & Holland 16g No 2 Back Action Sidelock. 30" x 2 3/4". 6lb 13oz.

The second was the H&H ‘flagship’ model, the Royal and

this example had HISTORY! Built in 1892, almost certainly as a 12g Paradox

ball and shot gun, we came across it at auction equipped with 30”

shotgun barrels. The barrels were thin, badly pitted, dented, bulged

and were beyond saving. In contrast to its origins, it again was an

excellent candidate for the drop-gauge treatment and recently joined

an original 12g 1890 cousin in the gun collection of one of our most

loyal customers.

Holland & Holland 16g Royal Sidelock Ejector No 11956. 30" x 2 3/4". 6lb 15oz

The fifth gun in this series was a bit of a departure for me. Built

as a 20g, this sweet little hammergun by WB Barratt featured a Purdey

thumblever, very rare in a small gauge, but the parlous state of the

barrels meant sleeving and she just cried out for conversion to 28g.

Here we kept to the original barrel length of 29”, rather than

increasing them to 30”, and the result was an absolute gem. When

undergoing pre-export testing, I totally fell in love with this gun

and, like the Westley 20/28 described above, I found she shot far better

than I could have hoped.

WB Barratt 28g Back Action Hammergun No 5099. 29" x 2 3/4". 5lb 8oz

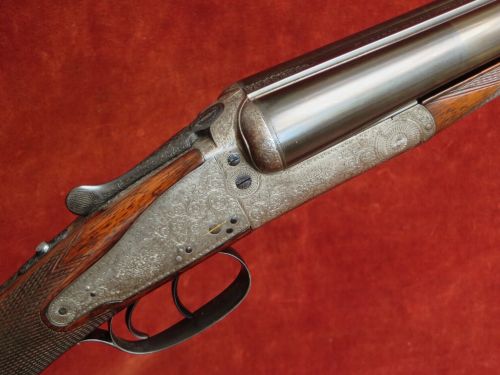

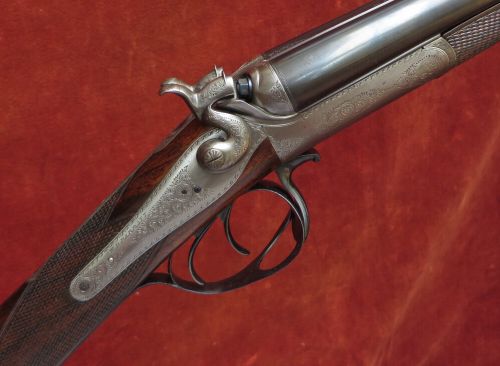

The last of the series so far is another gun intended for my personal

collection. A J Blanch & Son backaction sidelever hammergun, this

gun is also going to need a new stock which had been repaired badly

after a serious break at the wrist. However, what makes it all worthwhile

is the superb rose & scroll engraving: crisp with significant CH

remaining. I have already commissioned the TIG sleeving to 29”

x 16g x 2 ¾” with interchangeable thin-wall Teague chokes

in IC, ¼ & ½ (UK): a perfect gun for driven partridge

and early season driven pheasant with the open chokes or challenging

January pheasants with the tighter alternatives.

So there you have it: a series of serious game and clay guns built on

relatively heavy actions with wand-like barrels. They swing beautifully

and, weighing a bit more than one would expect for their adopted gauge

size, absorb recoil while not being inordinately heavy. This should

mean that the original wood, which is a feature of most of these guns,

is not unduly stressed during long chains of shots. Not to mention the

user...!

Please see our other categories...